- About

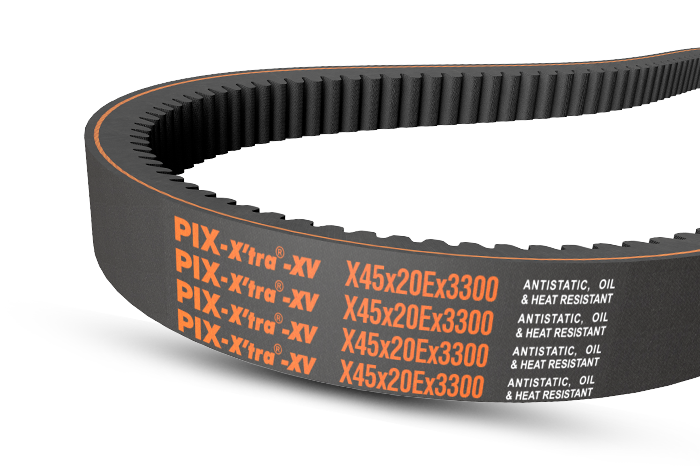

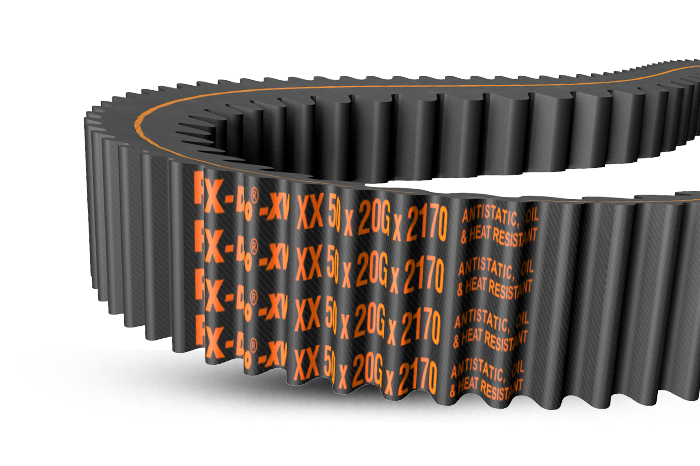

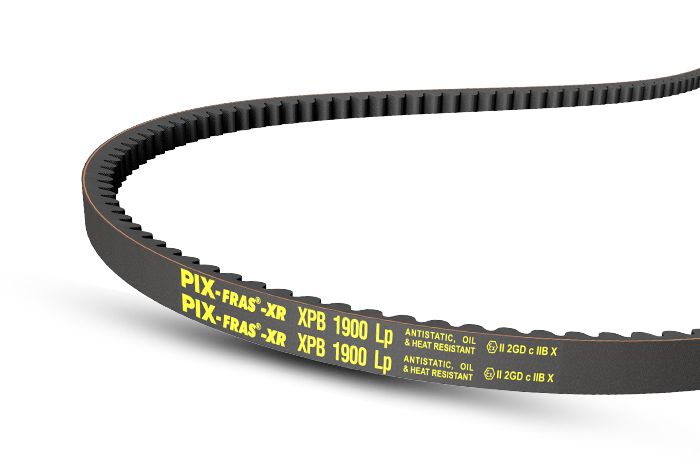

- Products

-

Applications

- Industrial

- Automotive

- Agriculture

- Lawn & Garden

- Ceramic

- Cold Storage

- Food Processing

- Domestic Appliances

- Cement

- Leisure & Sport

- Machine Tools

- Mineral Ore Mining

- Oil & Gas

- Packaging

- Paper & Pulp

- Pharmaceutical

- Power Plant

- Rice/Flour Mill

- Steel

- Textile

- Forestry & Wood Working

- Buildings & Construction

- Recycling

-

Accessories

PIX-Collapsible-Belt Length Measure

PIX-Collapsible-Belt Length Measure PIX-Belt Drive Service Kit

PIX-Belt Drive Service Kit PIX-Digital Tension Meter

PIX-Digital Tension Meter PIX-X'Align Lasertool

PIX-X'Align Lasertool PIX-Belt Length Measure

PIX-Belt Length Measure PIX-Analog Tension Tester

PIX-Analog Tension Tester PIX-Belt Profile Gauge

PIX-Belt Profile Gauge PIX-Pulley Gauges

PIX-Pulley Gauges PIX-Pulley Guage Banded Belts

PIX-Pulley Guage Banded Belts PIX-Pentagon Poly-V Belts Wear Gauge

PIX-Pentagon Poly-V Belts Wear Gauge PIX-Pentagon Timing Belt Wear Gauges

PIX-Pentagon Timing Belt Wear Gauges PIX-X'Slit Belt Cutting Machine

PIX-X'Slit Belt Cutting Machine

- Media

- Investors

- Sustainability

- Careers

- Contact