Heavy Duty V Belts

PIX offers a wide range of heavy duty v Belts, offering higher power rating, life and compact drives.

1. PIX-Muscle®-XR4; Superior, High-power, maintenance-free, Moulded Raw Edge Cogged Belts

2. PIX-Muscle®-XR3; High-power, Maintenance-free, Moulded Raw Edge Cogged Belts

3. PIX-Muscle®-XS3; High-power, Maintenance-free, Wrap Belts

4. PIX-Terminator®-HXS; Heavy-duty, High-power, Banded Wrap Belts

PIX-Muscle® series of heavy duty v Belts deliver high power ratings up to 50% over the standard Belts. They are recommended for high-temperature industrial drives, compressors, blowers, high power presses, hot rolling mills, textile industry, excavators, pumps and generators. High transmission efficiency up to 98%, resulting in enhanced productivity of these heavy duty v Belts and reduced cost of ownership.

PIX-Terminator® -HXS is heavy duty v belts, offering high power rating up to 70% over standard Wrap Banded Belts. They are widely used in applications involving vibrating screens, reclaimers, pulverisers, heavy-duty mixers, forestry woodcutters, wood chipping machines, etc.

The superior service life of these heavy duty v Belts ensures a higher return on investment.

PIX-X'set®-VS Variable-speed Wrap Belts

Experience the product

Our stunning interactive 3D Belt model allows viewers to get a hands-on experience with products by allowing them to view them from any angle or scale with rich rendering.

Features

- Excellent transverse rigidity and flexibility to prevent bucking at minimum diameter settings, where Belt stress is more

- Firm gripping action with the contact area provides positive traction for precise speed control

- Higher power transmission capacity

- Longer service life

- Facilitates smooth running without excessive vibrations

- Temperature range: -18°C to +80°C

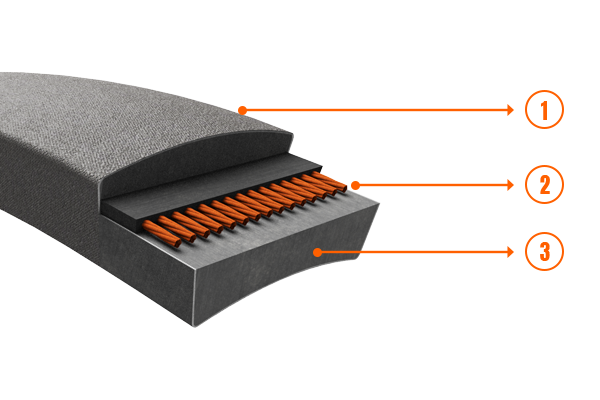

Constructional Details

- Wear-resistant bias-cut neoprene rubberised polyester cotton fabric

- High tenacity, low stretch, specially treated polyester cords

- Specially compounded high modulus compression rubber

Notes

Aramid cord construction Belts are available upon request

Reference Standard

ISO 3410:1989/ BS 3733: 1974

Applications

Variable speed pulley drives requiring exact speed control and maximum range of speed changes, Recreational equipment machine

Product Range

| Section | Angle (Degree) | Manufacturing Range | Length Desg. | ||||

|---|---|---|---|---|---|---|---|

| Min. (inch / mm) | Max. (inch / mm) | ||||||

| 25x13 / HI | 30 | 1200mm | 6584mm | La | |||

| 32x15 / HJ | 30 | 1225mm | 6596mm | La | |||

| 38x18 / HK | 30 | 1536mm | 9155mm | La | |||

| 45x20 / HL | 30 | 1668mm | 6628mm | La | |||

| 51x20 / HM | 30 | 1935mm | 10144mm | La | |||

| Non-standard sections | |||||||

| 15x9 | 40 | 571mm | 6502mm | Li | |||

| 19x11 | 40 | 1055mm | 3988mm | Li | |||

| 21x9 | 40 | 990mm | 3988mm | Li | |||

| 22x16 | 40 | 1727mm | 6502mm | Li | |||

| 30x12 | 30 | 1700mm | 6577mm | La | |||

| 40x20 | 30 | 920mm | 6628mm | La | |||

| 55x22 | 30 | 1967mm | 6640mm | La | |||

| 60x25 | 30 | 2011mm | 6659mm | La | |||

Product Label